+86 18876254353

+86 18876254353

+86 18876254353

+86 18876254353

After reading how the excavator is uphill, how many steps does it take to dig downhill? Are you usually in a downhill posture? What should you pay attention to during the downhill process? This issue will be shown through the six images.

The downhill work of the excavator can be divided into the following six steps:

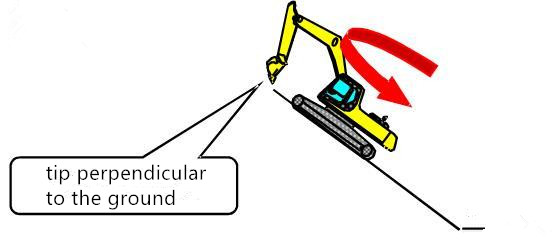

The first step: First, the arm of the excavator is vertically folded to the front, the tip of the tooth is perpendicular to the ground, and the bucket stays 180° at a height of about 10-20 cm from the slope surface.

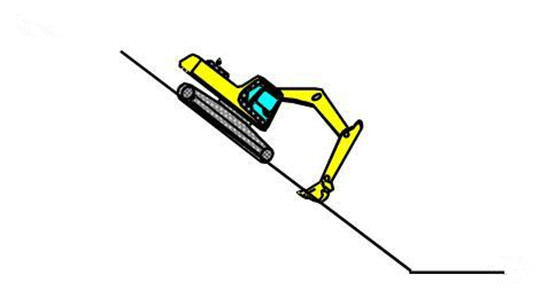

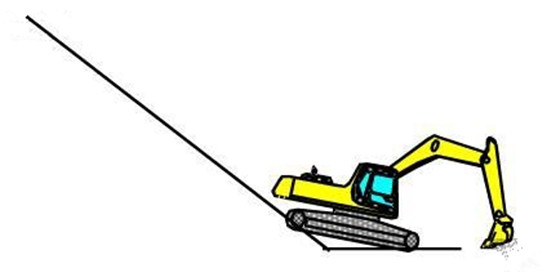

Step 2: As shown in the figure, the excavator's arm extends 20 to 30° in the vertical direction and the bucket is grounded.

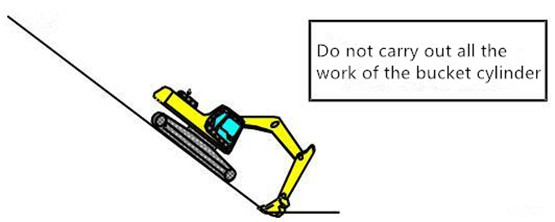

Step 3: The excavation level walks downhill at a low speed when the bucket is grounded. The bucket cylinder cannot be fully extended.

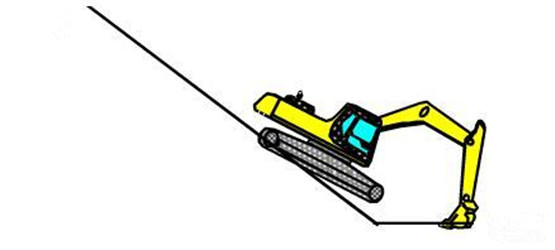

Step 4: When the excavator is approaching the end of the slope, the boom needs to support the ground so that the front of the track floats upwards. If the boom does not support the underground slope, the front of the track will be buried in the soil.

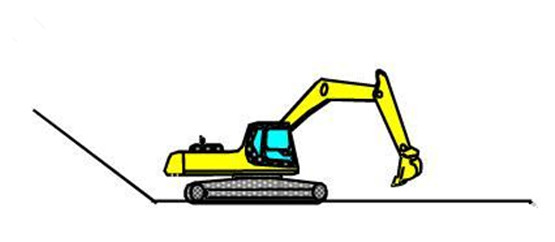

Step 5: As shown in the figure, go downhill by walking + arm excavation. When the front of the track reaches the end of the slope, you need to lift the boom to ground the front of the track.

Step 6: Finally, go downhill, the whole process is simple.

What do you need to pay attention to during the actual downhill process? The old driver finally gave you a summary of 6 mature experiences:

1. When it is very slippery on the exposed rock surface, it is best not to do this kind of work.

2. When there is snow or rain, it is easy to slip, do not climb downhill.

3. Pay attention to the terrain on the slope when going downhill. You need to clean the stone and walk.

4. Regardless of whether you are going uphill or downhill, remember to drive slowly and do not bend sharply on the slope.

5. Regardless of the size of the slope, the excavator's bucket must first land.

6. The more important point is that the operator remembers to fasten the seat belt.

online service

online service +86 18876254353

+86 18876254353 export5@vmgroup.cn

export5@vmgroup.cn Jay william

Jay william +86 18876254353

+86 18876254353