+86 18876254353

+86 18876254353

+86 18876254353

+86 18876254353

Although the undercarriage is a little iron guy, it is also very important for the excavator, and it is the most easily overlooked. The undercarriage parts is mainly include: track roller, carrier roller, front idler, sprocket and track link, commonly known as the four-wheeled belt.

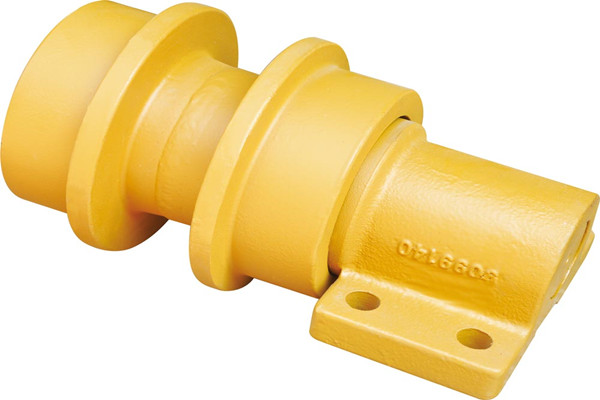

1. track roller: track roller is located under the X frame of the excavator. The 20-ton class is generally arranged on one side, and two of them will have track rail guards. In daily work, track roller should be avoided for a long time. In muddy water, ice and snow, after the work is completed every day, the unilateral crawler should be propped up, and the traveling motor will drive the mud and other debris on the track to be smashed. Especially in the winter construction, track roller must be kept dry, because the outer wheel of the roller There is a floating seal between the shaft and the shaft. If there is water at night, it will form ice. When the excavator is moved the next day, the seal will be scratched and contact with the ice, resulting in oil leakage. This is why the oil leakage of the roller occurs mostly. The reason for the winter. Damage to track roller will cause many failures. For example, if one side of track roller is damaged too much, the excavator may walk and run, and the walking is weak.

2. carrier roller: carrier roller is located at the platform position above the X frame, its role is to maintain the linear motion of the chain rail, such as the sprocket wheel damage will cause the track chain rail can not maintain a straight line, which is what we often say is the chain. The carrier roller is a one-time injection of lubricating oil. If oil leakage occurs, it can only be replaced with new ones. Therefore, it is necessary to keep the X-rail inclined platform clean. Do not allow too much accumulation of dirt to cause the carrier roller to rotate. Like the track roller, avoid wading).

3. front idler: front idler is located in front of the X frame. It consists of a guide wheel and a track adjuster assembly mounted inside the X frame. Keep front idler in front during work and walking, so as to avoid abnormal wear of the chain rail. The track adjuster assembly can also absorb the impact from the front pit road to reduce wear.

The track adjuster assembly consists of a coil spring and a track cylinder. The track cylinder can adjust the tension of the track by injecting grease (butter). Many people don't care about this detail, but once it has problems, the consequences will be very Severe, because its position is relatively low and in a relatively static state, long-term non-motion coupled with the action of water vapor in the air, the piston rod is easily rusted in the cylinder, and the regulation fails. The track cylinder needs regular oil draining and oil filling. The oil is drained - the grease cylinder will be released at most one turn, and the butter will be squeezed out from the oil drain (because the internal pressure is particularly large, the operator must stand on the side). While preventing the grease mouth from being ejected, causing casualties, oiling - tighten the grease fitting with a grease gun until the track is tightened to the proper position.

4. sprocket: sprocket is located behind the X frame, and the sprocket is composed of a travel motor, a travel reduction mechanism, and a travel ring gear. The traveling motor obtains the hydraulic energy from the main pump to realize the rotation, is decelerated by the traveling speed reduction mechanism, and then drives the crawler chain rail by the traveling ring gear mounted on the casing to realize the walking of the excavator.

The side of the sprocket must always be at the rear because it is directly fixed on the X frame and has no shock absorption function. If the sprocket is walking forward, it will not only cause abnormal wear on the drive ring gear and the chain track, but also adversely affect the X frame. The X frame may have problems such as early cracking. The travel motor guard can protect the motor while the internal space also stores some dirt and gravel, which will adversely affect the tubing of the travel motor. The water in the soil will corrode the joint of the tubing, gravel. It will interfere with the oil pipe and cause wear and oil leakage, so regularly open the guard to clean the dirt inside. When replacing the final transmission oil, the excavator should be parked on a flat ground, and the final drive should be transferred to the lowest position of the oil discharge port and perpendicular to the ground. When refueling, tighten the oil discharge screw plug and refuel from the upper fuel filler port. The oil can flow out.

5.Track link assy: Track link assy are mainly composed of track shoes and track links. Track shoes are divided into reinforcing plates, standard plates and extension plates. The reinforcing plate is mainly used in mine working conditions, the standard plate is used for earth working conditions, and the long plate is used for wetland working conditions. The wear of the track shoes on the mine is the most serious. When walking, the gravel will sometimes get stuck in the gap between the two plates. When it is turned into contact with the ground, the two plates will be squeezed, and the track shoes will be easily bent. Deformation, long-term walking will also cause cracking at the fixed position of the track shoe bolts. The Track shoes is rotated by the ring gear in contact with the drive ring gear. Excessive tightening of the track will cause early wear of the Track links, sprokect and front idler.

The measurement of the tightness is to park the excavator on a level surface, using a straight long rod on the track plate between the sprocket or the front idler and the carrier roller, and measure the maximum vertical distance between the track plate and the long rod. Generally, it is between 15-30mm; another method is to support one side of the track and measure the maximum vertical distance between the track shoes and the X frame. The value is generally between 320-340mm. According to the specific working conditions, appropriate adjustments can be made. For example, in mines, wetland operations can be 20-30mm, 340-380mm, and sand or snow and ice roads can be greater than 30,380mm.

The above is the daily maintenance and operation of the excavator undercarriage. If you also have the tips for daily work, please leave a message. export5@vmgroup.cn

online service

online service +86 18876254353

+86 18876254353 export5@vmgroup.cn

export5@vmgroup.cn Jay william

Jay william +86 18876254353

+86 18876254353